A major stormwater diversion was needed before the CRL’s cut and cover tunnels along Albert Street could be constructed.

The new stormwater main had to be constructed along the eastern side of Albert Street, between Swanson and Wellesley Streets. The construction was by pipe jacking (micro-tunnelling), replacing the existing line which currently runs along the centre of Albert Street.

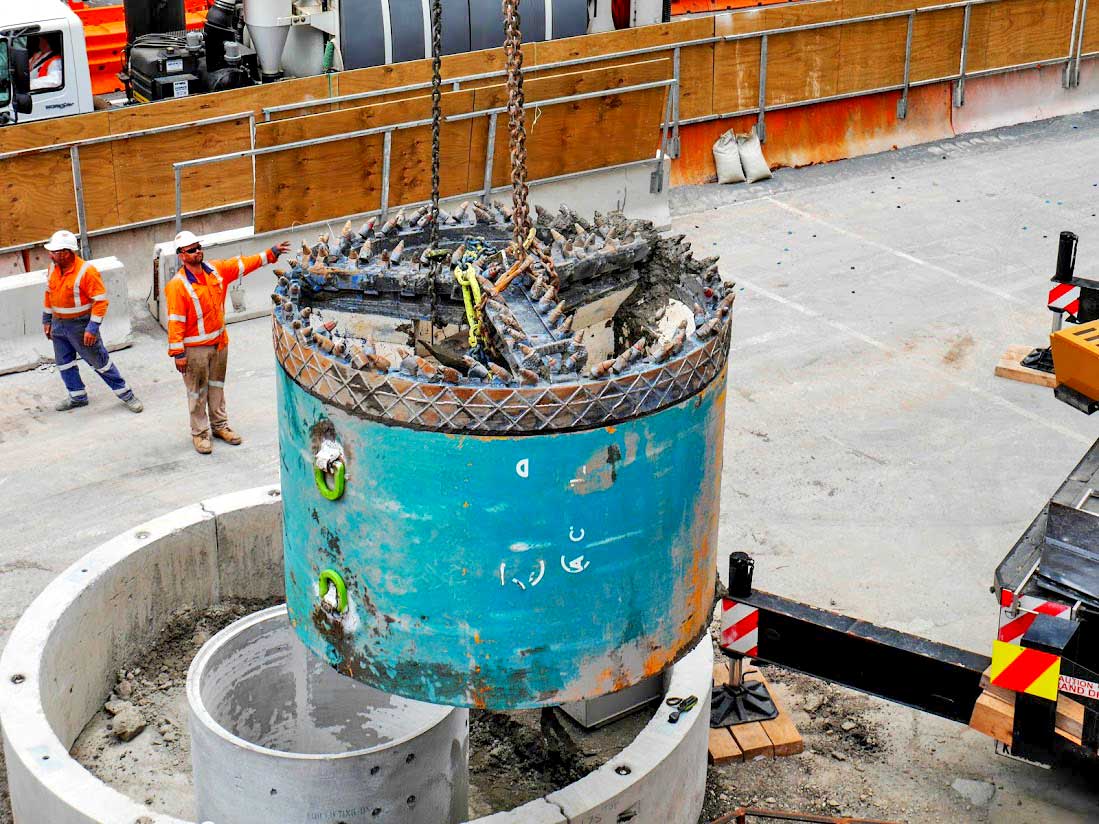

INSPECTION: Workers check the pipejack shaft at the end of the new stormwater shaft under Wellesley St

How pipe jacking works

Pipe jacking is a trenchless construction method used to install pipelines beneath highways, railroads, runways, harbours, rivers, and environmentally sensitive areas.

The 2m-wide tunnel boring machine, named Valerie in honour of the strength of Olympian Valerie Adams, simultaneously excavated and installed a new stormwater pipe under Albert Street.

A micro-tunnel boring machine (MTBM) drills a small tunnel under Albert Street installing the pipe as it goes.

Micro-tunnelling required a launch and reception shaft on the corner of Albert and Victoria Streets and reception shafts at Swanson and Wellesley Streets.

Powerful hydraulic jacks push specially designed pipes through the ground behind a cutting head that excavates the ground at the same time.

Swanson shaft

Benefits of pipe jacking

The micro-tunnelling and pipe jacking techniques provide a robust, finished, reinforced concrete pipeline as the tunnel is excavated whilst providing continuous ground support and minimising potential ground movement.

Safety is a prime advantage, especially in urban settings. Using an MTBM to excavate the ground keeps the majority of workers out of the tunnel, providing a far greater level of control over the rate of excavation and the management of different ground conditions.

Orakei Main Sewer

The Orakei Main Sewer (OMS) was originally constructed in 1910, and runs from Avondale, via Herne Bay and onwards to Hobson Bay, a total of over 8 km. The OMS varies in size from 525mm circular to 2.4m x 1.5m egg shape.

SEWER: (Photo: Sir George Grey Special Collections, Auckland Libraries, AWNS-19100804-16-4)

1910: The original Orakei Sewer Main running along the foreshore at Orakei

Part of CRL works included strengthening and bridging a section of the Orakei Main Sewer at Victoria Street West, to be undertaken as part of the Construction Contract 2 pipe jack programme.